钟表32.768KHZ晶振

TYPE: 308 32.768Khz-DIP

技 术 参 数 ELECTRICAL SECIFICATIONS

1

频率范围 Frequency Range

32.768KHZ

2

负载电容 Load Capacitance

12.5PF

3

激励功率 Drive Level

1.0uWMax

4

调整频差 Frequency Tolerance

±20PPM

At 25℃指定温度

5

二次温度系数 Temperature Coefficient

︱-0.035±0.01︳ppm/℃

6

工作温度范围 Operationg Temperature Range

-20~+70℃

7

贮存温度范围 Storage Temperature Range

-40℃~85℃

8

谐振电阻 Series Resistance

30KΩMax

At 25℃和频率有关

9

静态电容 Shunt Capacitance

1.75PF Typical

和频率有关

10

动态电容 Motional Capacitance

0.0035pf Typical

和频率有关

11

绝缘电阻 Insulation Resistance

<500MΩ

DC100V±15V

12

年老化率 Aging

±5PPM Max

25℃±3℃

13

拐点温度 Turnover Temperature

25±5℃

备注

外 形 尺 寸 REMARKS DIMENSIONS

石英晶振使用说明书

PROCESSING INSTRUCTIONS

■ 石英晶体意外跌落(When dropped by mistake)

设计和制造的石英晶体本身具有耐冲击能力,但是当石英晶体元件经受剧烈的机械冲击.如跌落到地板上或安装期间剧烈震动时,在使用之前需要进行电性能确认.

■ 焊接(Soldering)

(1) 引线型产品(Lead Type products)

① 使用电烙铁焊接时,引线应该在3秒内焊接完毕,电烙铁温度不能高于300℃

Lead wires should be soldered within 3 seconds with the soldering iron heated to a temperature no higher than 300℃’

② 使用浸锡方式焊接时,引线应该在10秒内焊接完毕,焊锡温度不能高于260℃,并且注意不能将整个晶体浸锡,推荐使用垂直安装方式,避免热力直接传导到晶体上.

In solder-dip processing,the leads should be soldered within 10 seconds with a temperature no higher than 260℃.Mounting in upright is recommendable to prevent the heat conduction directly to the body of the crystal unit.

■ 石英晶体剪脚(To bend the lead of cylinder type products)

① 当圆柱状晶体组件需要剪脚时,为了防止剪脚时造成 密封玻璃体的破裂,从剪脚处到晶体基座底部距离应该大于1.5mm,推荐距离3.0mm,并使用工装夹具进行剪脚.

When the lead of cylinder type crystal units need to be bent ,leave more than 1.5mm(3.0mm is recommendable) of lead from thecase in order to prevent from any cracks of the hermetic sealing glass at the root of the lead ,and use a jig to bend if possible.

② 当圆柱状晶体组件进行剪脚时,不要剥离引线的镀层.

When bending the lead of cylinder type crystal units,do not scrape off the soldering off the soldering plating from the lead surface.

■ 元件的安装(Mounting)

圆柱状晶体元件的安装 Mounting of cylinder type products

① 为了避免影响元件电性能或损坏元件,严禁将圆柱状晶体元件外壳焊接在印制板上进行固定,推荐使用橡胶粘结剂进行固定.

Soldering the body of the cylinder type crystal units with PCB must be avoided due to deteriorate the characteristics or damage the products.Rubber adhesive is recommended.

② 当用手工来弯曲引线时,请遵照下列方法.

When the lead needs to be bent by hand, please follow the instruction as below:

用手指捏住圆柱晶体的外壳,用镊子夹住引线要弯曲的部位,该部位离晶体基座底部1.5mm以上(推荐3.0mm);用镊子夹住弯曲引线成90°,不要用力拉引线,用力拉引线可能造成引线根部的玻璃珠破裂,而产生漏气损坏元件电性能.

Hold the body of the cylinder type crystal units in fingers; pick at the part with tweezer,which you want to bend .there should be more than 1.5mm (3.0mm is recommended)from the body case.

Bend the lead 90°by tweezer without pulling the lead strongly. If pulling the lead strongly may cause any cracks of hermetic sealing glass at the root of the lead and may cause the leakage and the characteristics to deteriorate.

■ 石英晶体元件的贮存

石英晶体元件长时间贮存在高温或高湿环境中,可能会影响频率的稳定性和可焊性,请将晶体组件贮存在正常的温度和湿度环境中,避免阳光直射和露水凝结,避免贮存6个月以上再使用,拆封后尽快装配使用.

Storage of the crystal units under higher temperature of high humidity for a long term may affects frequency stability or solderability .please store the crystal units under the normal temperature and humidity without exposing to direct sunlight and dew condensation ,and avoid the storage of crystal units for more than 6 months ,and mount them as soon as possible after unpacking.

供应圆柱晶振206

信息内容:、 一、技术规格 1.盒 型:Φ2×6 2.振动模式:基频 3.标称频率: 6.000MHz 4.调整频差:±20ppm(at 20±2℃) 5.温度频差:±20PPM 6.负载电容:20PF 7.谐振电阻:200Ω max 8.静态电容:7.0pF max 9.激励功率:10μW 10.年老化率:±5ppm/year 11.绝缘阻抗:500MΩ(DC100±15V) 12.测试仪器:1240 13.标 记: 6.000 二、机械和环境性能 1.自由跌落(冲击):从35cm高度自由跌落到2cm厚的胶 板上,跌落3次,跌落后晶体频差不可超过5ppm。 2. 振动:频率10~55Hz,振幅0.75mm,X Y Z方向各振动 30分钟。 频率变化≤±...

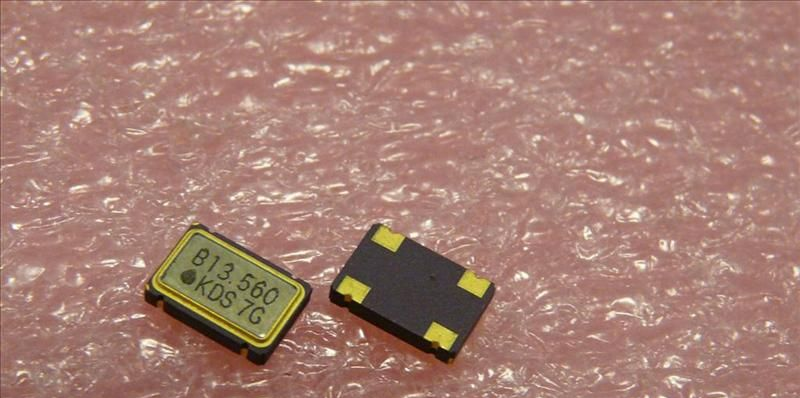

供应无源KDS贴片晶振507

信息内容:连云港耀科电子有限公司:厂家供应贴片晶振507 石英晶振 晶振工厂 贴片晶体507 晶振厂家 振荡器 半尺寸晶振 全尺寸晶振 钟振 机顶盒用晶振 安防晶振 车载DVD晶振 汽车晶振 表晶32.768KHZ 圆柱晶振12M 晶体谐振器 贴片晶振 圆柱晶振 晶振12M 家电用晶振 晶振的作用 贴片晶振3225 SMD晶振 455E晶振 49T晶振 麦克风晶振 无线晶振 电路板晶振 陶瓷晶振 陶振 主营产品:石英晶振 贴片晶振 表晶32.768 49S晶振 晶振工厂 石英管 加热管 碳纤维加热管 卤素加热管 石英片 石英坩埚 石英棒