Nine-Axis (Gyro + Accelerometer + Compass) MEMS MotionTracking™ Devices

Overview

Click to Enlarge

The MPU-9x50™ family of parts are the world’s first 9-axis MotionTracking

devices designed for battery operated, high performance consumer electronics

products.

The 9-axis product family incorporates the same market proven MotionFusion™

and run-time calibration firmware that is supported in InvenSense’s market

leading MPU-6000 and MPU-3000 family of products. This firmware has shipped in

millions of units and has been very well market validated.

9-Axis MotionTracking has become a key function in many consumer electronics

devices including smartphones, tablets, gaming consoles, and smart-TVs. The size

advantage of the integrated 9 axis devices versus a discrete solution is

compelling for space constrained products such as smartphones and wearable

sensors.

The MPU-9x50 devices combine a 3-axis gyroscope, 3-axis accelerometer and

3-axis compass in the same chip together with an onboard Digital Motion

Processor™ (DMP™) capable of processing the complex 9-axis MotionFusion

algorithms.

The MPU-9x50 family is comprised of parts listed in the table below.

MPU-9X50 System Diagram

供应应美盛(invensense)九轴传感器 MPU9150 MPU-9150

信息内容:The MPU-9250 is the company’s second generation 9-axis MotionTracking device for smartphones, tablets, wearable sensors, and other consumer markets. The MPU-9250, delivered in a 3x3x1mm QFN package, is the world’s smallest 9-axis MotionTracking device and incorporates the latest InvenSense design innovations, enabling dramatically reduced chip size and power consumption, while at the same time improving performance and cost. The MPU-9250 MotionTracking device sets a new benchmark for 9-axis performance with power consumption only 9.3µA and a size that is 44% smaller than the company’s first-generation device. Gyro noise performance is 3x better, and compass full scale range is over 4x better than competitive offerings. The MPU-9250 is a System in Package (SiP) that combines two chips: the MPU-6500, which contains a 3-axis gyroscope, a 3-axis accelerometer, and an onboard Digital Motion ProcessorTM (DMPTM) capable of processing complex Motion...

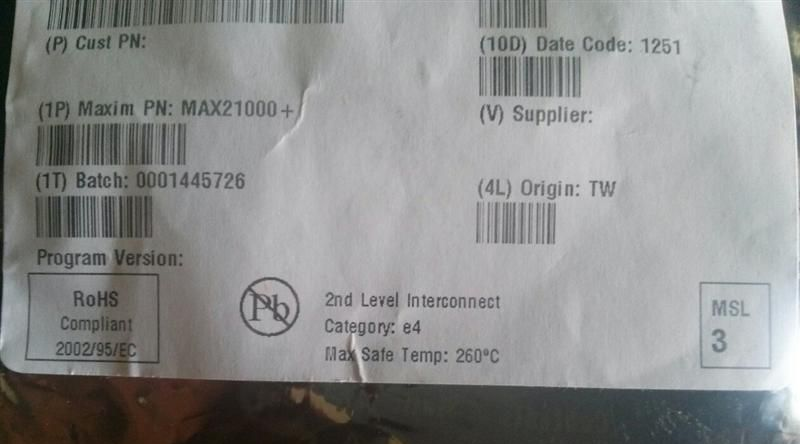

供应3轴陀螺仪传感器MAX21000+

信息内容:General Description The MAX21000 is a low power, low noise, 3-axis angular rate sensor that delivers unprecedented accuracy and sensitivity over temperature and time. It operates with a supply voltage as low as 1.71V for minimum power consumption. It includes a sensing element and an IC interface that provides the measured angular rate to the external world through a digital interface (I 2 C/SPI). The IC has a full scale of ±31.25/±62.50/±125/±250/ ±500/±1k/±2k degrees per second (dps) and measures rates with a finely tunable user-selectable bandwidth. The high ODR and the large BW, the low noise at highest FS, together with the low phase delay, make the IC suitable for both user interface (UI) and optical image stabilization (OIS) applications. The IC is a highly integrated solution available in a com- pact 3mm x 3mm x 0.9mm plastic land grid array (LGA) package...