品牌:HWA 型号:MF72/MF11/10D-5/5D-7/8D-7/33D-7/5D-9/8D-9/10D-9/22D-9/33D-9/5D-11/8D-11/10D-11 种类:热敏 性能:通用 材料:合成 温度系数:NTC 营销方式:厂家直销 产品性质:热销

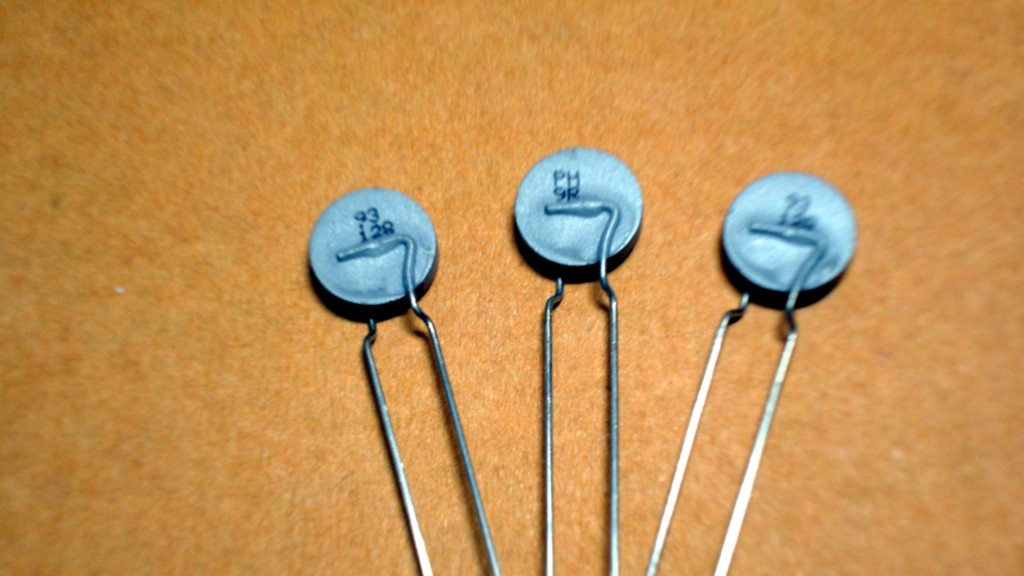

欧蓝达电子的NTC热敏电阻器系由特殊配置的金属氧化物陶瓷材料制成,它可用来抑制高的突波电流。相对于受保护电路,热敏电阻器具有较高的电阻。因此会抑制突波电流约1~2秒,在这一段时间内热敏电阻的电阻将因温度升高而下降,直至热敏电阻两端压降到可被忽略的电阻值为止。如图A以电源供应器为例, 在电源开的瞬间,电容器一般阻抗极低,桥式整流器通常承受很大的电流,热敏电阻器特别使用于保护电源供应器。

olanda electronic NTC Thermistor devices are made of a specially formulated metal oxide ceramic material which is capable of suppressing high inrush current surges.

Thermistor devices, being of relatively high resistance, shall limit the inrush current for 1~2 seconds during which time the device decreased in resistance substantially to a point where its voltage drop is negligible .The devices are especially useful in power supplies (see Fig A) because of the extremely low impedance of the capacitor being charged, of which the bridge is ususlly subjected to an exceedingly high current surge at turnon point.

特征

●有效抑止突波电流。

●稳定状态下功率损耗极小(通常仅有1W或小于50W)。

●热及电特性稳定性高。

●宽广的电性规格可供选择。

FEATURES

●High inrush current restriction effect

●Small power loss in stationary state

●(Normally less than 50W power)

●High thermal and electrical stability.

●Wide selection of electrical performances

应用概述

如图B所示,将一NTC热敏电阻与一白热灯丝串联时,可以消除突波电流。若一只NTC热敏电阻无法提供足够之突流限制功能时,二只或更多的热敏电阻可用于串联电路上或供应电路的各个分路上(如图A)。但要注意的是NTC热敏电阻,不可并联于电路上,因为其中一只NTC就可能会传导几乎所有的电流。热敏电阻用于图A所示AC电路的A1或A2处,或是DC电路D1或D2处。

在设计上,当电路刚被打开的瞬间,NTC热敏电阻的阻值高于电路上所有白热灯丝的总电阻值。当电流开始通过时,热敏电阻随时产生「自然」现象,并在1到2秒内,阻值会降到几可忽略。以同样的构想来看电动马达的突波电流,亦可以被抑制到限度。图C表示应用热敏电阻保护直流马达前后突波电流波形的差异。

APPLICATION

As shown in Fig.B, the current surge can be eliminated by placing a NTC thermistor in series with a filament string. Yet, if the resistance of one NTC thermistor does not provide sufficient inrush current limiting functions for your applicantion, 2 or more may be used in series or in separate legs of the supply circuit (Fig.A). Be noticed, the thermistor can not be used in parallel since one unit will tend to conduct nearly all the current available. Thus, thermistor may be used in the AC (point A1or A2)or the DC (point D1or D2) locations in the circuit. (see Fig.A)

The resistance of NTC thermistor is designed higher than the total resistance of NIC thermistor is designed higher than the total resistance of filaments when thermistor shall immediately self-heat. Then, in 1~2 seconds, its resistance will be reduced to a minimum and become insignificant to the total resistance of a circuit. With the same concept, current surges in electric motors can be held to minimum. Fig.C shows a typical DC motor's turn on surge before and after the application of a thermistor to the circuit

选用原则

1.热敏电阻器的工作电流>实际电源回路的工作电流

2.热敏电阻器的标称电阻值

R≥ 式中E为线路电压 l m为浪涌电流

对于转换电源、逆变电源、开关电源、

UPS电源l m=100倍工作电流

对于灯丝、加热器等回路l m=30倍工作电流

1.Maximum operating current >Actual operating current in the power loop

2.Reted zero power resistance at 25℃

of which, E: loop voltage, lm: Surge current.

For conversion power, reversion power, switch power,

UPS power, lm=100 times. operating current

For filament, heater, lm=30 times operating current

电压电流特性

当NTCR热敏电阻在小电流下工作时(如图F),由于功率太底,其电阻保持固定而表现线性关系(符合欧姆定律V/R=1)。如果电流增加,NTC热敏电阻就会产生焦耳效应(P =V×1)而使自己发热,其电阻值随即减小表现「电流增加,电压下降」的状态。

When operating low current (see fig.F), due to very low power is unable to make the NTC thermistor self-heated, so its resistance value is thus maintained constant and displayed with a linear curve (in conformity with ohm-law V/R=1).If the current is increased, the NTC thermistor will follow Joule-efficiency(P= V×1) and make itself self-heated that results in a resistace value decreasing and thus displays with a status of voltage descending while current increased.

(如图F),说明NTC元件与环境达成热平衡所需的时间,主要决定于材料热容量(G)及散热系数(δ)。当元件温度由T1降到T0,则可得到下列平衡式:

-HdT=δ(T-T0)dt 其中-HdT=元件热损失

δ(T-T0)dt:元件散热量

积分后可得温度与时间关系式T-T1= (T0-T1)×e-t/t

其中τ=H/δ

As shown in fig.G which explains the time needed to reach thermal equilibrium of NTC components with the enviroment. This characteristic depends on two important parameters. If a step change in temperature is applied to a component e.g. form high (T1) to low (T0) temperature, the energy lost (δ(T0-T1)dt) by the component (-HdT) is equal to the energy dissipated by it.

-HdT=δ(T-T0)dt

This equation yields: T-T1= (T0-T1)×e-t/t

τ=H/δ

- 所属城市:广东 深圳

- [联系时请说明来自维库仪器仪表网]

- 联系人: 浮振宁

- 电话:0755-29411600

- 传真:0755-29411600

- 手机:

- QQ :

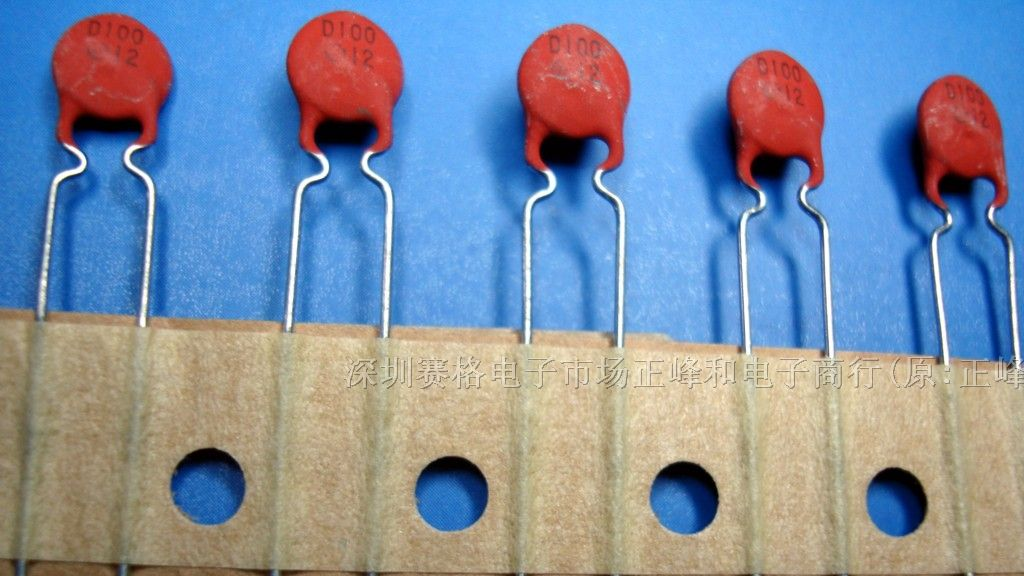

供应PPTC过流保护片

信息内容:品牌:HWA 型号:PPTC/250V/60V/90V/250V 种类:热敏 性能:通用 材料:合成 制作工艺:合成式 外形:平面片状 温度系数:PTC 功率特性:小功率 营销方式:厂家直销 产品性质:热销高分子PTC热敏电阻工作原理介绍高分子PTC热敏电阻用于过流保护1.PTC效应说一种材料具有PTC (Positive Temperature Coefficient)效应,即正温度系数效应,仅指此材料的电阻会随温度的升高而增加。如大多数金属材料都具有PTC效应。在这些材料中,PTC效应表现为电阻随温度增加而线性增加,这就是通常所说的线性PTC效应。2.非线性PTC效应经过相变的材料会呈现出电阻沿狭窄温度范围内急剧增加几个至十几个数量级的现象,即非线性PTC效应,如图1所示。相当多种类型的导电聚合体会呈现出这种效应,如高分子PTC热敏电阻。这些导电聚合体对于制造过电流保护装置来说非常有用。3.高分子PTC热敏电阻用于过流保护高分子PTC热敏电阻又经常被人们称为自恢复保险丝(下面简称为热敏电阻),由于具有独特的正温度系数电阻特性(即PTC特性,如图1所示),因而极为适合用作过流保护器件。热敏电阻的使用方法象普通保险丝一样,是串联在电路中使用,如图2所示。当电路正常工作时,热敏电阻温度与室温相近、电阻很小,串联在电...

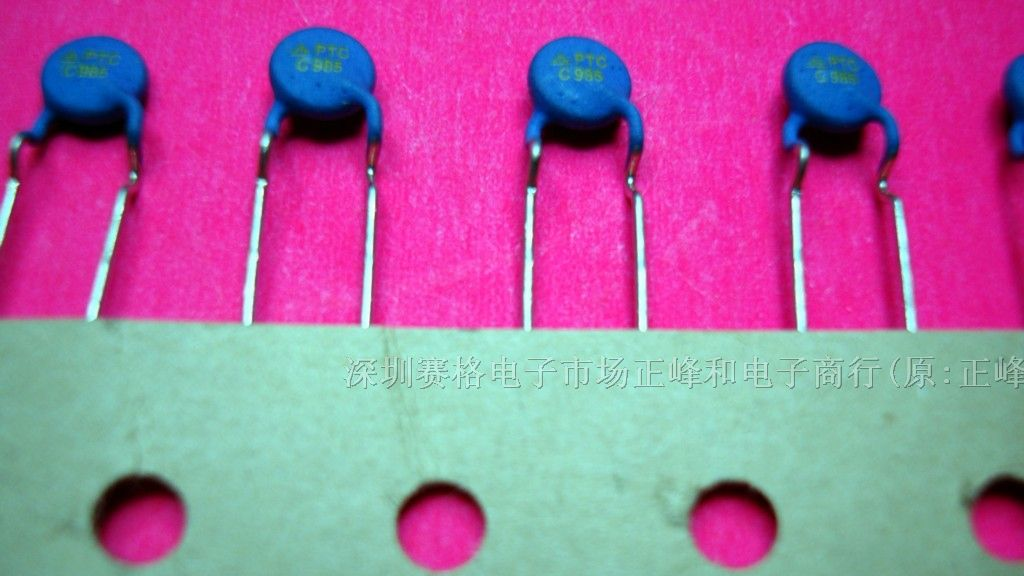

供应PTC恒温加热器

信息内容:品牌:HWA 型号:MZ4/PR4/MZ1/MZ2/MZ3/MZ4/MZ5/MZ6/MZ7/MZ8/MZ11/MZ12/MZ12A/MZ11A/MZ11B/50S/75S 种类:热敏 性能:通用 材料:合成 制作工艺:合成式 温度系数:PTC 营销方式:厂家直销 产品性质:热销恒温发热热敏电阻器恒温加热PTC热敏电阻恒温加热PTC热敏电阻具有恒温发热特性,其原理是PTC热敏电阻加电后自热升温使阻值进入跃变区,恒温加热PTC热敏电阻表面温度将保持恒定值,该温度只与PTC热敏电阻的居里温度和外加电压有关,而与环境温度基本无关. PTC加热器就是利用恒温加热PTC热敏电阻恒温发热特性设计的加热器件.在中小功率加热场合, PTC加热器具有恒温发热、无明火、热转换率高、受电源电压影响极小、自然寿命长等传统发热元件无法比拟的优势,在电热器具中的应用越来越受到研发工程师的青睐.PTC加热器按传热方式分类: (1) 以热传导为主的PTC加热器.其特点是通过PTC发热元件表面安装的电极板(导电兼传热 )、绝缘层(隔电兼传热)、导热蓄热板(有的还附加有导热胶)等多层传热结构,把PTC元件发出的热量传到被加热的物体上. (2) 以所形成的热风进行对流式传热的各种PTC加热器.其特点是输出功率大, 并能自动调节吹出风温和输出热量. (3) 红外辐射PTC加热器....