ATS616LSG Dynamic Self-Calibrating Peak-Detecting Differential

Hall Effect Gear Tooth Sensor

dzsc/13/4516/13451627.jpg

Features and Benefits

• Self-calibrating for tight timing accuracy

• First-tooth detection

• Immunity to air gap variation and system offsets

• Eliminates effects of signature tooth offsets

• Integrated capacitor provides analog peak and valley information

• Extremely low timing-accuracy drift with temperature changes

• Large air gap capability

• Small, integrated package

• Optimized magnetic circuit

• Undervoltage lockout (UVLO)

• Wide operating voltage range

dzsc/13/4516/13451627.jpg

Description

The ATS616 gear-tooth sensor is a peak-detecting device that uses automatic gain

control and an integrated capacitor to provide extremely accurate gear edge detec-

tion down to low operating speeds. Each sensor module consists of a high-tem-

perature plastic shell that holds together a samarium-cobalt magnet, a pole piece,

and a differential open-collector Hall IC that has been optimized to the magnetic

circuit. This small package can be easily assembled and used in conjunction with a

wide variety of gear shapes and sizes.

The gear-sensing technology used for this sensor module is Hall-effect based. The

sensor incorporates a dual-element Hall IC that switches in response to differential

magnetic signals created by ferrous targets. The sophisticated processing circuitry

contains an A-to-D converter that self-calibrates (normalizes) the internal gain

of the device to minimize the effect of air-gap variations. The patented peak-

detecting filter circuit eliminates magnet and system offsets and has the ability to

discriminate relatively fast changes such as those caused by tilt, gear wobble, and

eccentricities. This easy-to-integrate solution provides first-tooth detection and

stable operation to extremely low rpm. The ATS616 can be used as a replacement

for the ATS612LSB, eliminating the external peak-holding capacitor needed by

the ATS612LSB.

The ATS616 is ideal for use in systems that gather speed, position, and timing

information using gear-tooth-based configurations. This device is particularly

suited to those applications that require extremely accurate duty cycle control or

accurate edge-detection, such as automotive camshaft sensing.

TheATS616 is provided in a 4-pin SIP that is Pb (lead) free, with a 100% matte

tin plated leadframe.

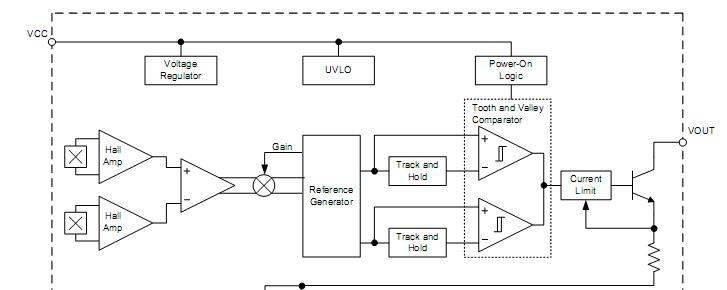

Functional Block Diagram

dzsc/13/4516/13451627.jpg

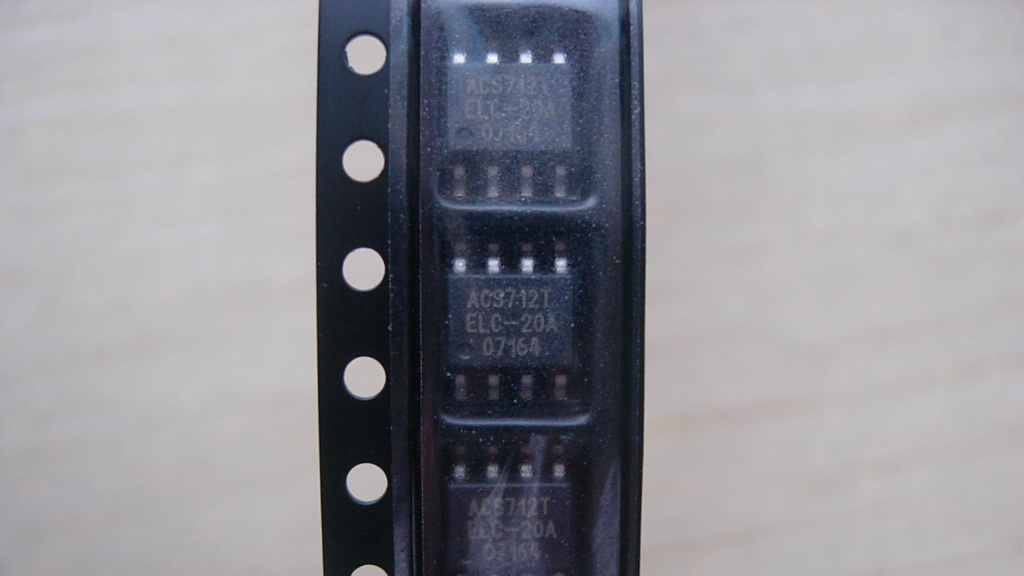

供应 原装电流传感器 ACS712ELCTR-20A

信息内容:特点 低噪音模拟信号路径 可通过新的滤波引脚设置器件带宽 5 µs 输出上升时间,对应步进输入电流 80 千赫带宽 总输出错误 1.5%(当 TA = 25°C 时)及 小型低厚度 SOIC8 封装 1.2 mΩ 内部传导电阻 引脚 1-4 至 5-8 之间 2.1 VRMS 最小绝缘电压 5.0 伏特,单电源操作 66 至 185 mV/A 输出灵敏度 输出电压与交流或直流电流成比例 出厂时精确度校准 极稳定的输出偏置电压 近零的磁滞 电源电压的成比例输出

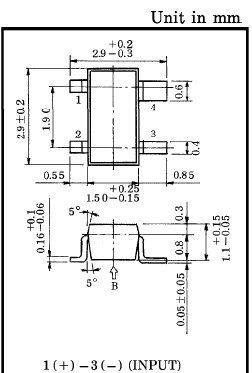

供应 TOSHIBA霍尔传感器 THS124

信息内容:THS124HIGH STABILITY MOTOR CONTROL.DIGITAL TACHOMETER.CRANK SHAFT POSITION SENSOR. dzsc/13/4516/13451629.jpg